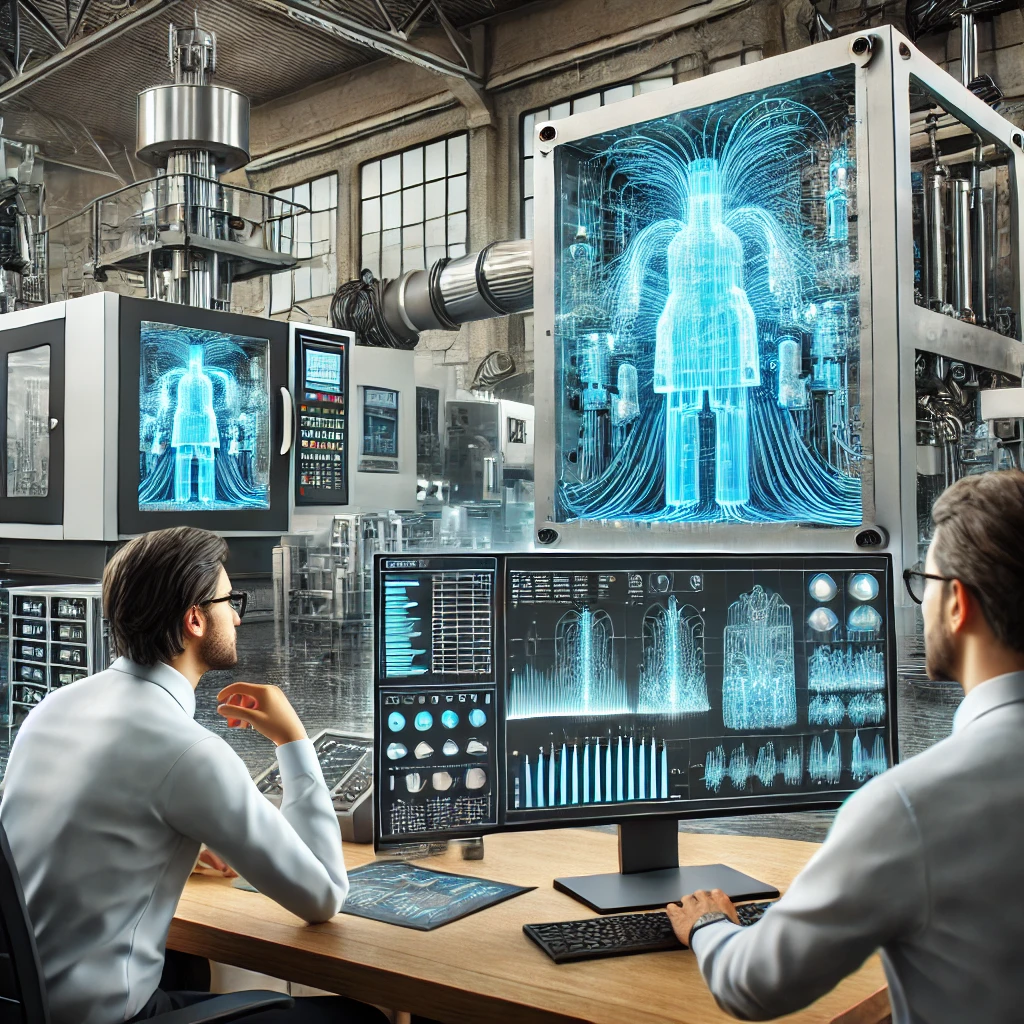

Plastic Mold Flow Analysis

We specialize in providing Mold Flow Analysis Services in Delhi NCR, India, to ensure the design and production of quality plastic parts.

Core Analysis Capabilities

Our services include:

- Fusion: Simulating material fusion for consistent quality.

- Flow: Analyzing material flow patterns to optimize filling.

- Cool: Assessing cooling efficiency to avoid defects.

- Warp: Predicting and preventing warping during production.

Procedure and Benefits

Our mold flow analysis supports the injection molding process before cutting tool steel, offering significant advantages:

- Cost-Effective Design: Eliminate trial-and-error methods with detailed analysis reports.

- Time Efficiency: Reduce setup time and optimize the production process.

- Optimal Tool Layout: Arrive at precise tool layouts and runner designs.

- High-Quality Output: Achieve quality plastic injection molded parts on the first attempt.

- Predictive Insights:

- Optimal weld line placement.

- Prediction of short shots for enhanced production reliability.

Why Choose Us?

- Experienced Engineers: Our team brings rich expertise in mold tool design and analysis.

- Tailored Solutions: Custom analysis to meet specific part and tool requirements.

- Comprehensive Reporting: Detailed insights to support decision-making and reduce costs.

- Customer-Centric Approach: Focused on building better plastic parts with improved efficiency and performance.