Quality Inspection Services

Our quality inspection services use advanced 3D scanning and CMM (Coordinate Measuring Machine) technology to help customers verify products against CAD models or 2D drawings with high precision.

Key Inspection Methods

-

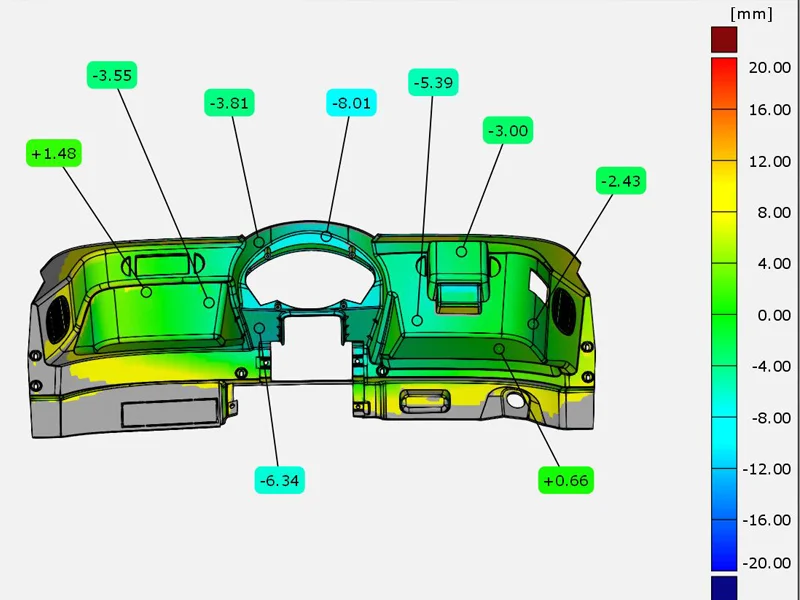

Surface Deviation Inspection

- Compares the product’s surface against an existing CAD model.

- Identifies deviations and ensures accurate replication of the design.

-

Dimensional and GD&T Check

- Verifies dimensions and Geometric Dimensioning and Tolerancing (GD&T) based on input 2D drawings.

- Ensures the product adheres to all specified tolerances.

Advantages of Our Quality Inspection Process

- High Accuracy: Advanced tools ensure reliable and precise measurements.

- Production Optimization: Surface Deviation and Dimensional Analysis help reduce production line downtime.

- Detailed Reporting: Comprehensive reports highlight deviations and guide corrective actions.

Applications

- Suitable for industries requiring precise part verification, such as automotive, aerospace, and manufacturing.